1. Material Compatibility

● Key Point: The two materials used must be compatible in terms of adhesion, melting points, and shrinkage rates.

● Consideration: Ensure that the materials bond well together to avoid delamination or weak interfaces.

2. Mold Runner System

● Key Point: A cold runner system is often used to separate the two materials until they reach the mold cavity.

● Consideration: Proper design of the runner system is crucial to prevent material contamination and ensure smooth flow.

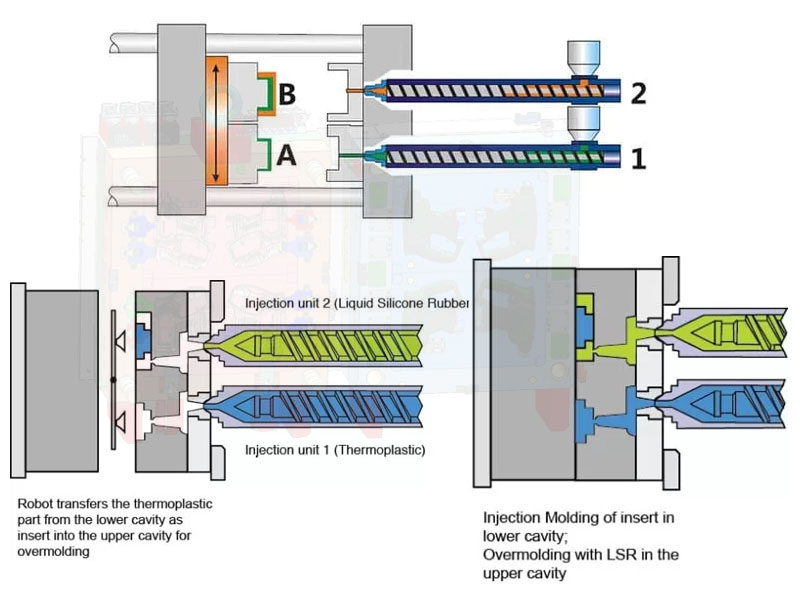

3. Rotary or Core-Back Mold

● Key Point: The mold must be designed to accommodate the two-color process, typically using a rotary or core-back mechanism.

● Consideration: The mold should allow for precise alignment and movement to ensure accurate material placement.

4. Injection Molding Machine

● Key Point: A specialized two-color injection molding machine with two injection units is required.

● Consideration: The machine must be capable of handling the two materials simultaneously or sequentially with high precision.

5. Process Parameters

● Key Point: Control over injection speed, pressure, temperature, and cooling time is critical.

● Consideration: Optimize these parameters to ensure proper material flow, bonding, and part quality.

6. Mold Temperature Control

● Key Point: Maintaining consistent mold temperature is essential for achieving uniform part quality.

● Consideration: Use mold temperature controllers to manage the heat distribution and prevent defects like warping or sink marks.

7. Part Design

● Key Point: The design of the part must facilitate the two-color molding process.

● Consideration: Incorporate features like overmolding areas, undercuts, and proper wall thickness to ensure successful molding.

8. Quality Control

● Key Point: Implement rigorous quality control measures to detect and address any defects early in the process.

● Consideration: Use inspection techniques such as visual checks, dimensional measurements, and adhesion tests to ensure part integrity.

By carefully considering these eight essential elements, manufacturers can achieve high-quality, durable, and visually appealing two-color molded parts. Each element plays a crucial role in the overall success of the process, from material selection and mold design to process control and final inspection.

+86 13421913167

+86 13421913167

E-mail

E-mail