Injection Molding for Plastic Caps From Design to Production

Design

● Injection Molding Cap Design:Function and Appearance

Design the cap to meet its specific functional requirements, such as sealing tightly, being easy to open and close, and having a certain capacity. At the same time, consider the aesthetic appearance to make it attractive to consumers.

Material Selection: Choose suitable plastic materials based on the cap's intended use. Common materials include polyethylene (PE), polypropylene (PP), and polystyrene (PS). For example, PP is often used for its good chemical resistance and high-temperature resistance.

Structural Design: Design the internal and external structure of the cap, including the thread shape, wall thickness, and any additional features like ribs for strength. The thread design should ensure a secure fit with the container. The wall thickness needs to be uniform to avoid issues like warping during molding.

● Injection Mold Design:

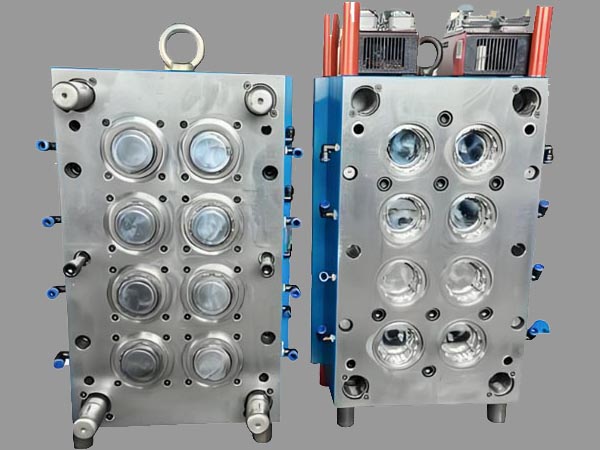

Cavity Layout: Determine the number of cavities in the mold based on production volume and efficiency. Multiple cavities can be used to produce several caps in one molding cycle, but it requires careful balance to ensure uniform filling and cooling.

Gating System: Design the gating system to control the flow of the molten plastic into the mold cavity. The gate location and size affect the filling pattern and the quality of the molded cap. For example, a side - gate may be used for a simple cap design to ensure smooth filling.

Cooling System: A well - designed cooling system is crucial to ensure uniform cooling of the plastic cap. This helps to reduce warping and shrinkage. Cooling channels are placed in the mold to circulate coolant and maintain an even temperature distribution. nbsp;

Production

● Mold Manufacturing:○ Machining: The mold is typically made of steel or aluminum. High - precision machining processes such as computer - numerical - control (CNC) milling and EDM (electrical - discharge machining) are used to create the detailed cavity and core shapes according to the mold design.

○ Surface Treatment: The mold surface may undergo treatments like polishing or texturing. Polishing gives a smooth finish to the caps, while texturing can add features such as anti - slip surfaces or decorative patterns.

● Injection Molding:

○ Material Preparation: The plastic pellets are dried to remove any moisture, as moisture can cause defects in the molded parts. They are then fed into the injection molding machine's hopper.

○ Injection Process: The plastic is heated in the barrel of the injection molding machine until it reaches a molten state. It is then injected into the mold cavity under high pressure. The injection pressure, speed, and temperature are carefully controlled to ensure proper filling of the cavity.

○ Cooling and Solidification: After injection, the mold is cooled to allow the plastic to solidify. The cooling time is optimized to achieve the right balance between production speed and part quality. Once solidified, the mold opens, and the finished cap is ejected.

● Quality Control:

○ Dimensional Inspection: Check the dimensions of the caps using measuring tools like calipers and gauges to ensure they meet the design specifications. Any deviations can affect the cap's fit and function.

○ Visual Inspection: Inspect the caps for surface defects such as scratches, bubbles, and warping. Aesthetic defects can impact the product's marketability.

○ Functional Testing: Test the caps for their sealing ability, ease of opening and closing, and other functional requirements. For example, a leak - test may be performed to ensure the cap provides a proper seal.

● Post - Processing:

○ Trimming and Deburring: Remove any excess plastic flash or burrs from the caps. This can be done manually or using automated trimming equipment.

○ Assembly: If the cap has multiple components, such as a cap with a liner or a tamper - evident band, assemble these components accurately.

○ Packaging: Package the finished caps in appropriate packaging materials, such as boxes or bags, to protect them during storage and transportation.

One-stop injection molding manufacturer - SOMETOOL is specialized in the design and fabrication of plastic injection mold, die casting mold, and injection molding. If you are interested in this kind of product, please feel free to contact us. We will be pleased to be at your service.

+86 13421913167

+86 13421913167

E-mail

E-mail