Key Components of Automotive Injection Molds

Automotive molds are complex and typically include:

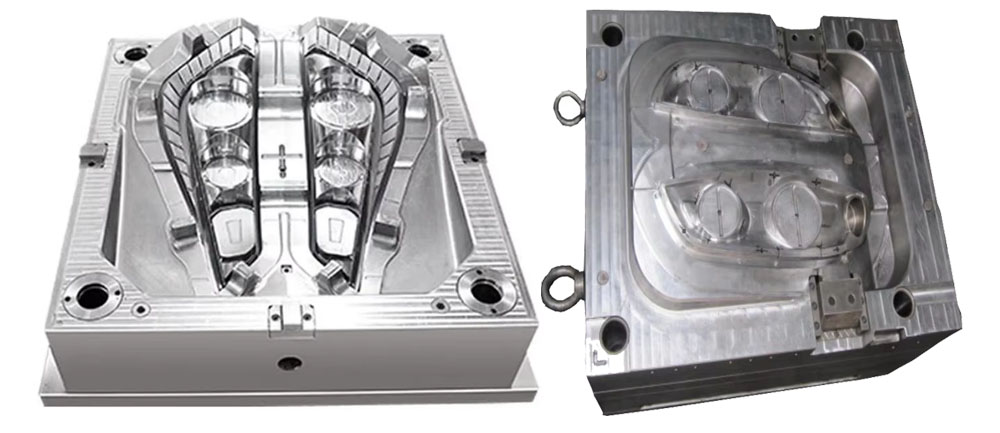

1. Cavity and Core Plates

○ The primary components that form the shape of the plastic part.

2. Gating System

○ Channels that direct molten plastic into the mold cavity (e.g., sprue, runner, gate).

3. Cooling System

○ Channels for circulating coolant (e.g., water) to solidify the plastic quickly and uniformly.

4. Ejection System

○ Mechanisms (e.g., ejector pins) to release the finished part from the mold.

5. Ventilation System

○ Small openings to allow air escape during injection, preventing defects like voids.

Design Considerations for Automotive Molds

1. Material Selection

○ Mold Materials: High-grade tool steels (e.g., H13, S136) or aluminum alloys for durability and heat resistance.

○ Plastic Materials: Polypropylene (PP), ABS, nylon, or engineering polymers (e.g., PEEK) based on part requirements (e.g., heat resistance for under-the-hood components).

2. Precision and Tolerances

○ Tight tolerances (often ±0.05 mm) to ensure parts fit seamlessly in assemblies (e.g., interior trim, structural components).

○ Surface finish requirements (e.g., glossy, matte, or textured surfaces for aesthetics).

3. Complex Geometry

○ Undercuts, multi-slider mechanisms, or collapsible cores for parts with intricate shapes (e.g., door handles, air vents).

4. Cycle Time Optimization

○ Efficient cooling systems to reduce solidification time and increase production speed.

○ Hot runner systems to minimize material waste and improve consistency.

5. Compliance with Standards

○ Meets automotive industry regulations (e.g., ISO 16949, TS 16949) and safety requirements (e.g., flame retardancy for interior parts).

SOMETOOL(SAM Precison Molds) is not only an custom injection mold maker but also an injection molding manufacturer. In the mean time we have been striving to be your one stop solution shop so we can make cost-down for valued clients. We imported various kinds of facilities in terms of secondary operations and assemblies. Insert moulding, over moulding, two-shot & three-shot injection molding are all within our business scope. Send us your designs - we're ready to make them a reality.

+86 13421913167

+86 13421913167

E-mail

E-mail