1. Pre-Trial Preparation

● Review Mold Design & Specifications

Check the mold drawings, material selection, and part design (shrinkage, draft angles, etc.).

Confirm gate location, cooling channels, and ejection system.

● Inspect the Mold

Ensure the mold is clean and free of damage.

Verify that all moving parts (ejector pins, sliders, cores) function smoothly.

● Select the Right Machine

Match the mold size and tonnage requirements with the injection molding machine.

Ensure the machine’s shot capacity, clamping force, and plasticizing rate are suitable.

● Prepare Material

Dry the plastic resin if necessary (e.g., nylon, PET).

Set the correct melt temperature based on material specs.

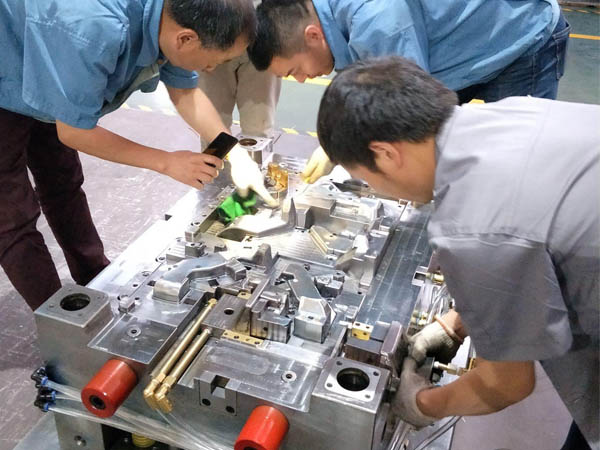

2. Mold Installation

● Mount the Mold

Secure the mold onto the machine’s platens and align it properly.

Connect cooling lines and ensure no leaks.

● Set Up Process Parameters

Input initial settings (temperature, injection speed/pressure, cooling time, etc.).

Use recommended settings from the material supplier or previous trials.

3. Initial Trial Run (Short Shot Test)

● Perform a Short Shot

Inject a small amount of plastic to check flow behavior.

Identify flow marks, air traps, or filling imbalances.

● Adjust Parameters

Increase injection speed/pressure if the part doesn't fill completely.

Modify temperature settings if there are flow issues.

4. Full Injection & Process Optimization

● Run Full Cycles

Produce complete parts and check for defects (sink marks, warping, flash, etc.).

Adjust packing pressure and cooling time to minimize shrinkage.

● Optimize Ejection

Ensure parts eject smoothly without sticking or damage.

Adjust ejection speed, force, or add release agents if needed.

● Check Dimensional Accuracy

Measure critical dimensions against CAD specs.

Compensate for shrinkage by fine-tuning mold temperature or holding pressure.

5. Defect Troubleshooting

| Defect | Possible Cause | Solution |

| Short Shots | Low injection pressure/speed, cold mold | Increase pressure/speed, raise mold temp |

| Flash | Excessive clamping force, over packing | Reduce injection pressure, check mold alignment |

| Sink Marks | Insufficient cooling/packing | Increase packing pressure, extend cooling time |

| Warping | Uneven cooling, high stress | Optimize cooling channels, reduce melt temp |

| Jetting | High injection speed | Reduce speed, modify gate design |

● Run Stability Tests

Produce multiple batches to ensure consistency.

Monitor cycle time and part quality over extended runs.

● Document Settings

Record optimal machine parameters for future production.

Note any mold modifications needed (e.g., venting, gate adjustments).

● Customer Approval

Submit samples for approval before mass production.

7. Post-Trial Mold Maintenance

● Clean and lubricate the mold.

● Address any wear or damage observed during the trial.

SOMETOOL Team with about 60 experienced engineers, technicians and toolmakers are dedicated to pursuing customer satisfaction, if you need custom plastic mold, please contact us for your owm mold design and trial.

+86 13421913167

+86 13421913167

E-mail

E-mail