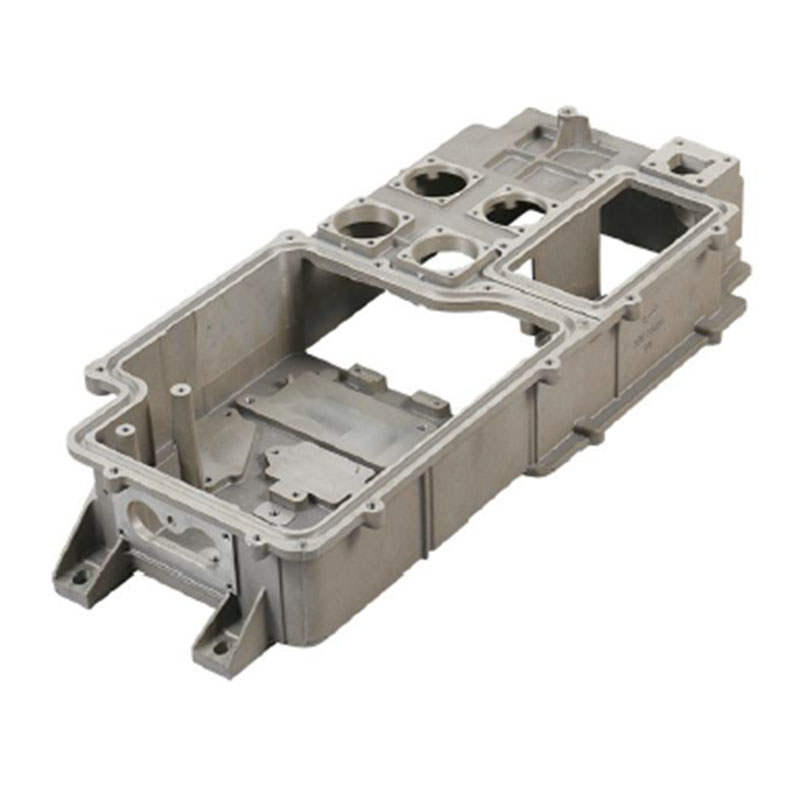

Die Casting Toolings Features

● Advanced CAD Software

Using advanced CAD software is essential in the design phase. It allows for the creation of precise and detailed 3D models and provides tools for simulating the casting process to identify potential issues before the mold is manufactured.

● Mold Design

Once the part design is complete, the focus shifts to designing the mold itself.

Why Choose SOMETOOL

SOMETOOL is specialized on reliable and high quality precision injection molds, die casting and injection molding.

- 01Export experience 10 years

- 02Exported mold 5000 sets

- 03Daily output 100,000 pieces

- 04Have 60 sets high precision machines

- 04Have 60 sets high precision machines

- 05Have 15 experienced engineers

Manufacturing Ability

There are four times to detect the production.

● First, using electronic to measure copper.

● Second, inspection after CNC machine in case of occuring quality defect and production returned to be repaired.

● Third, inspection before mold assembly for making sure the accuracy necessary to perfectly assemble mold.

● Finally, when the production finished ,we will inspect the quality of production.

Solutions

SOMETOOL service include automotive, medical, electronics, smart home, daily necessities, etc.

+86 13421913167

+86 13421913167

E-mail

E-mail